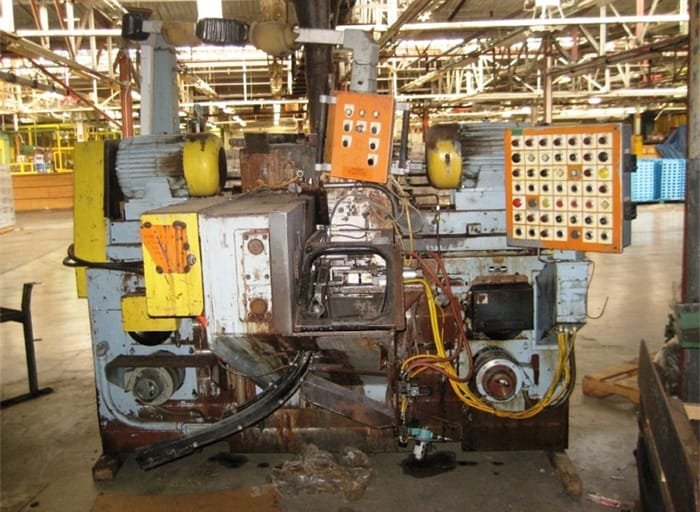

Gardner Double-Disc Grinder Rebuild Case Study

Known for its outstanding technology, superior quality and exceptionally innovative spirit, a well-respected global bearing manufacturer contacted GCH Machinery to rebuild one of its warehoused Gardner double-disc grinding machines. The grinder, vintage mid-1980s, was headed toward a central Asian bearing production line and needed a full remanufacture to meet the needs of this quality-conscious company.

GCH Machinery’s first task in this machine tool rebuilding project was to examine the grinding application and requirements to look for ways to improve the double-disc grinding process and then to assess exactly what would turn this piece of equipment into an advanced grinding machine.

Next came a redesign of the Gardner double-disc grinder’s mechanical, hydraulic, pneumatic, lubrication, cooling and gaging modules. A number of machine upgrades, exclusive to GCH Machinery, were added, including a new servo infeed to provide more accurate movement of the slides, and a new servo dresser to simplify machine structure and improve surface finish of the part. New THK slides were added to improve quality of the work part and reduce machine downtime and vibration.

The machine tool rebuilding project resulted in a state-of-the-art grinder that exceeded OEM specifications and could hold a less-than-one- (1) micron tolerance.

Are you saddled with an older grinding machine?

Learn more about GCH Machinery grinder remanufacturing by reading about our remanufacturing services or viewing other machine tool rebuilding examples.

BEARINGS COMPANY PUTS UPGRADED GRINDER BACK IN SERVICE FOR 4” BEARINGS (FACE GRINDING)

Gardner Double Disc

Contact Us

Request for Quote

Fields marked with an asterisk are required.